The olive canning industry has been around for centuries, with the process of canning olives dating back to ancient times. Today, the industry has evolved to include modern technology and machinery that makes the process more efficient and cost-effective.

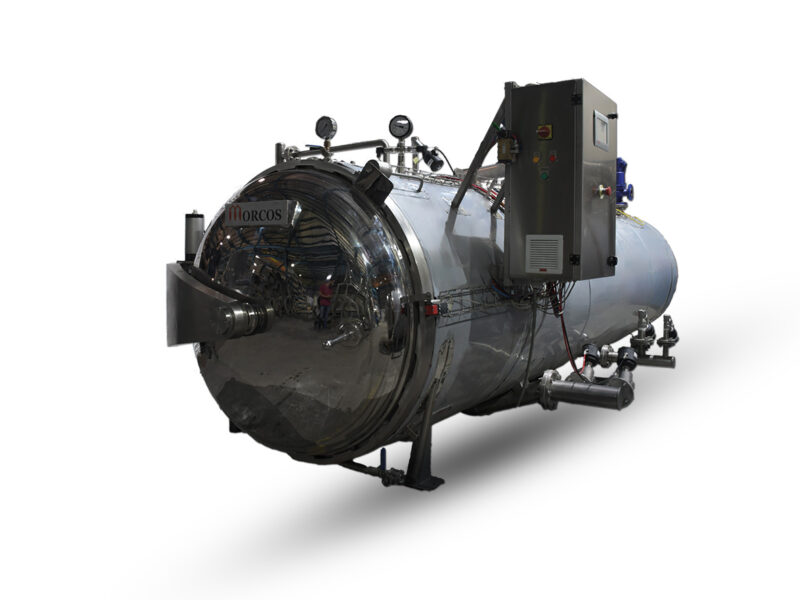

Canning is the process of preserving food in airtight containers, such as cans or jars. In the olive canning industry, this process involves washing and sorting olives before placing them in cans. The cans are then sealed and sterilized using an autoclave, which uses high-pressure steam to kill any bacteria or microorganisms that may be present.

Shower fillers are used to fill the cans with brine or other liquids before they are sealed. Palletizers and de-palletizers are used to stack and unstack pallets of cans, respectively. Loaders and unloaders are used to move the cans from one area of the factory to another.

Olives come in many different varieties, each with its own unique flavour profile. Some popular varieties include Kalamata olives, which are known for their rich flavour and meaty texture, and green olives, which have a milder flavour and firmer texture.

In addition to being a delicious snack on their own, olives are also used in a variety of dishes, including salads, pizzas, and pasta dishes. They are also a popular ingredient in Mediterranean cuisine.

The olive canning industry plays an important role in preserving this beloved food for consumers around the world. With modern technology and machinery at their disposal, olive canning companies can produce high-quality products efficiently and cost-effectively.