Machine Details

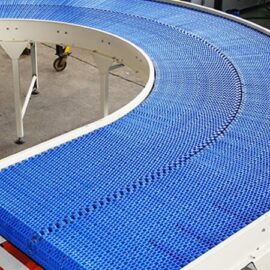

For biscuits aligning and stacking consists of channeling board, acceleration conveyor, transfer shaft, layering conveyors.

- Effective widths of 900 to 1800 mm

- PU belt of food proofed material.

- Total Stainless-Steel chassis and belt bed.

- Operation length of 4000 – 5000 mm.

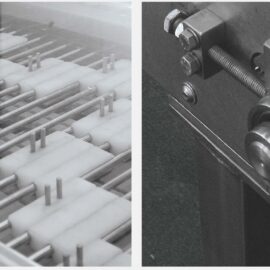

- Stacking begins at the channeling corrugated board, made for one product size with its own modulating motor. (Step 1)

- Acceleration conveyor receives product and pass it the transfer shaft which is responsible for handling the accelerated products to the next and final step. (Steps 2 & 3)

- Finally, the layering conveyor stacks the coming products in layers ready to be delivered to the packing station conveyors. (Step 4)

- Another layering conveyor can be added depending on the customer production process needs, and in this case, it will be Step 5.

- All Penny Stacker equipment (conveyors) are driven by European made gear drive motors with infinitely variable speed control frequency inverters.

- Automatic pneumatic belts tracking and tensioning stations with air pistons at both sides of all equipment (conveyors).

- Equipped with Stainless-Steel products guides.

- Control panel with a touch screen displaying operation data for all equipment (conveyors).